What materials and coating technologies are commonly used in OMTD film manufacturing?

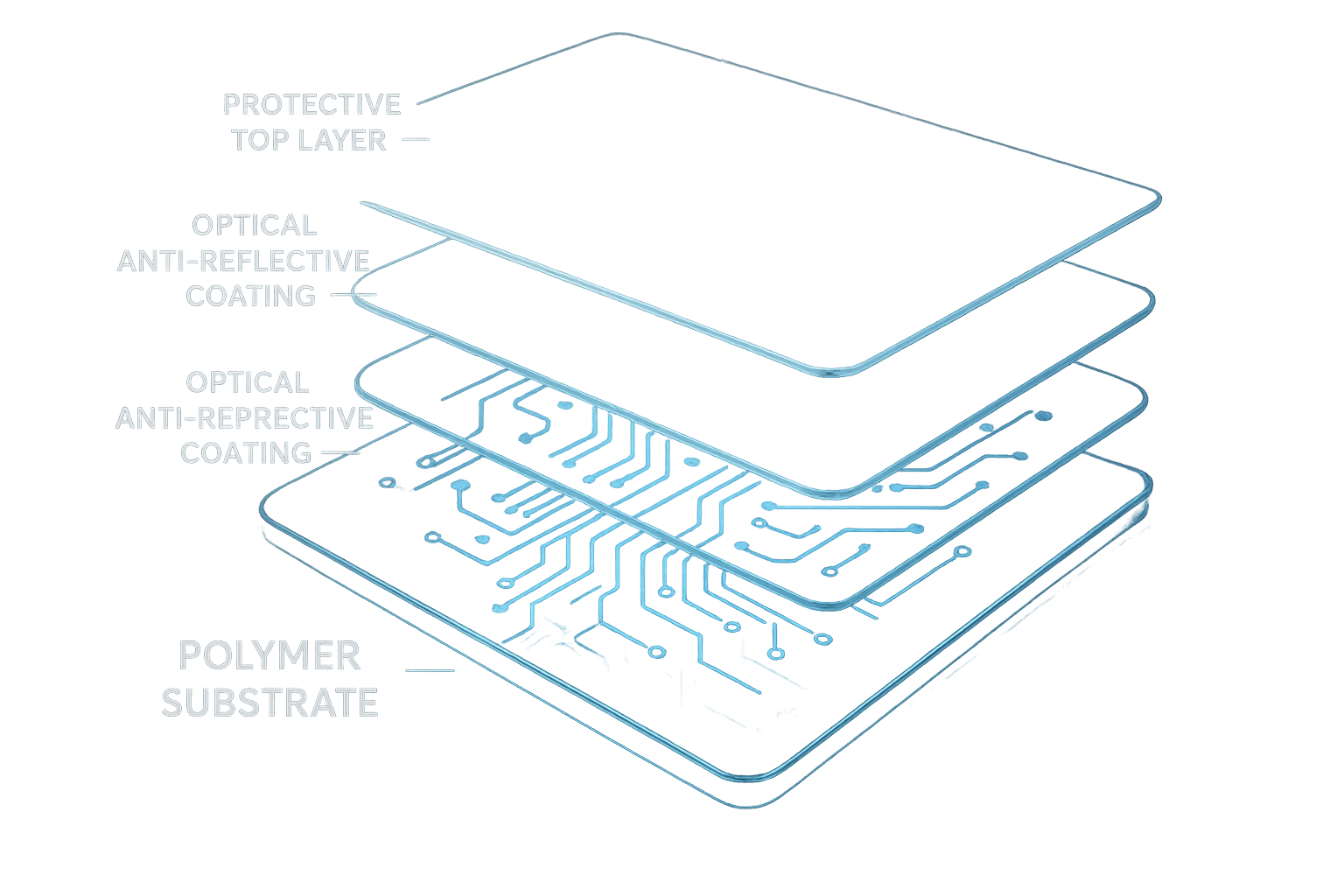

Optoelectronic Mapping Transparent Display (OMTD) film represents a breakthrough in transparent display technology, combining optical clarity with precise electronic performance. Its structure and composition are the result of advanced material engineering and coating processes designed to achieve both high transparency and reliable conductivity. Understanding the materials and coating technologies behind OMTD film helps explain why it has become an essential component in transparent displays, heads-up displays, and next-generation smart windows.

1. Base Substrate Materials

The foundation of OMTD film typically consists of high-transparency polymer substrates that provide both mechanical stability and optical clarity. Common materials include:

- Polyethylene Terephthalate (PET): Offers excellent optical transmittance, flexibility, and cost efficiency. It is widely used in flexible display applications.

- Polycarbonate (PC): Known for high impact resistance and good dimensional stability, PC substrates are often used when mechanical durability is critical.

- Polyimide (PI): Suitable for high-temperature applications and flexible electronics due to its thermal stability and bending endurance.

- Glass Substrate: For rigid displays, ultra-thin glass provides superior optical flatness and minimal distortion.

These substrates form the structural base upon which the optoelectronic layers are deposited.

2. Conductive Layer Materials

The conductive layer is the functional core of OMTD film, enabling electrical current flow without compromising transparency. Several advanced materials are employed depending on the design requirements:

- Indium Tin Oxide (ITO): A long-established transparent conductive oxide with excellent conductivity and optical performance, though it has limitations in flexibility and cost.

- Silver Nanowires (AgNWs): Provide superior flexibility and low sheet resistance, making them suitable for bendable transparent films.

- Graphene: Offers high electrical conductivity, mechanical strength, and transparency, with growing interest as a next-generation conductive layer material.

- Metal Mesh: Composed of microscopic metallic grids (often silver, copper, or nickel), metal mesh coatings achieve very low resistance while maintaining high optical transmittance.

- Conductive Polymers (e.g., PEDOT:PSS): Used for flexible applications, conductive polymers balance transparency, flexibility, and processability.

The selection of conductive material depends on application needs, cost, and the desired balance between conductivity and optical performance.

3. Optical Coating Technologies

To enhance visual quality, OMTD films often incorporate optical coatings that manage light reflection, transmission, and color uniformity. Common optical coatings include:

- Anti-Reflective (AR) Coatings: Minimize glare and reflection losses to improve display clarity.

- High-Refractive Index Layers: Used to control light path and reduce scattering, enhancing overall brightness and color contrast.

- Optical Compensation Layers: Balance birefringence or angular color shift in displays, ensuring uniform color performance.

These coatings are typically applied using precision thin-film deposition methods such as sputtering, evaporation, or chemical vapor deposition.

4. Functional Layer Coatings

Beyond optical and conductive layers, OMTD films often include functional coatings for enhanced durability and performance:

- Hard Coatings: Increase surface hardness and scratch resistance, especially for outdoor or automotive applications.

- Hydrophobic and Oleophobic Coatings: Repel moisture, oil, and fingerprints to maintain clear visibility.

- UV and Infrared (IR) Filtering Layers: Protect the film and underlying electronics from ultraviolet degradation and control thermal radiation.

- Adhesion Promoters and Buffer Layers: Improve bonding between different material layers and prevent delamination under mechanical stress.

5. Coating and Deposition Processes

The performance of OMTD film is highly dependent on the precision of its coating technologies. Advanced manufacturing processes used include:

- Magnetron Sputtering: A physical vapor deposition technique for creating uniform conductive or optical coatings with high adhesion strength.

- Atomic Layer Deposition (ALD): Allows precise control of film thickness and composition at the atomic level, used for ultra-thin functional coatings.

- Roll-to-Roll (R2R) Coating: Enables high-volume, continuous production of flexible OMTD films with consistent quality.

- Inkjet or Spray Coating: Used for patterning conductive materials like silver nanowires or polymers onto flexible substrates.

Each process is selected based on the target application, cost structure, and required material performance.

6. Integration and Application

After coating, the different layers are integrated into a composite OMTD film that offers both optical transparency and electronic mapping functionality. This integrated structure can be customized for diverse applications such as transparent OLED panels, augmented reality displays, vehicle HUD systems, or smart retail signage.

The combination of advanced material science and precise coating engineering ensures that OMTD films maintain high optical transmittance (often exceeding 90%), low surface resistance, and robust environmental stability—key factors in transparent display performance.

In summary, OMTD film manufacturing relies on a synergistic blend of transparent polymer or glass substrates, conductive materials like ITO, silver nanowires, or graphene, and optical and protective coatings applied through advanced deposition techniques. As research continues, improvements in material flexibility, conductivity, and environmental endurance are expected to expand the range of OMTD film applications across next-generation display and optoelectronic technologies.

English

English русский

русский Español

Español عربى

عربى